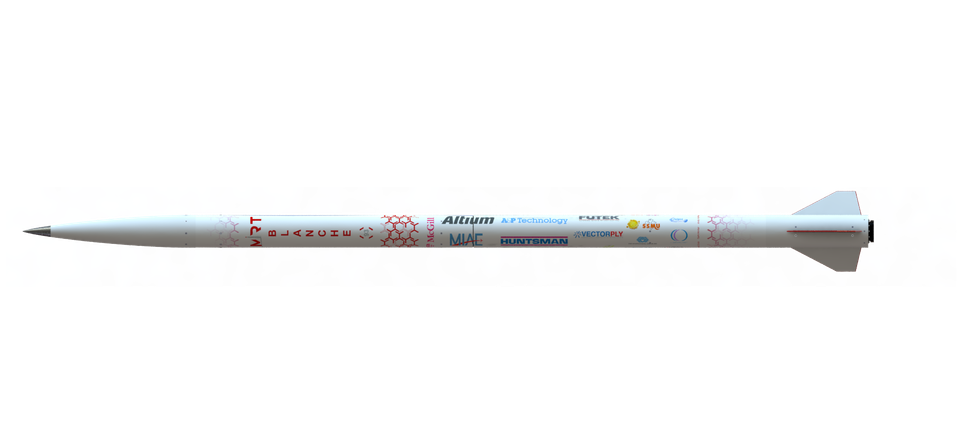

Project Blanche (2018)

Blanche 10K COTS

The 2018 IREC marks McGill’s 4th year participating in the competition. The Project Blanche is the successor to Project Aeris, the team’s 10,000 ft COTS category entry. Following the difficulty recovering Aeris, the team has fundamentally reworked the recovery system design and airframe manufacturing process to prevent the same issues from reoccurring.

To further validate the changes, the team has built a secondary rocket, Bertrand, which flew on a test launch on June 2nd, 2018. However, manufacturing an entirely separate rocket to test critical recovery and avionic systems increased financial costs. In order to help offset the additional costs, the group expanded the number of student-made components, replacing off-the-shelf pieces.

Only 3 of the 53 major components in Blanche were off-the-shelf - being the motor itself, the avionic redundancy, and a motor retaining ring. Student made components such as parachutes, shock cords, CO2 ejectors, tender-descenders, and the airframe lead to cost savings of several thousand dollars.

The aero-structure subsystem features a composite airframe manufactured in-house using a refined resin infusion process. This method was perfected over the course of the year and allows for high quality, tight dimensional tolerance composite structures as well as reduced lead times.

The avionics are centralized in a radio-transparent fiberglass airframe section, as well as telemetry module in the nose cone. The telemetry systems are triply-redundant, and the parachute deployment is doubly-redundant. The centralized avionic section allows for rapid, convenient assembly, and easy access to the ejection charges located in the forward parachute chamber.

A single separation point is located at the nose cone, where a deployable payload will eject,intended to measure micro-organism density in the atmosphere.

275.63 m/s

Results:

Spaceport America Cup 2018:

- 10K Category: 1st/47

- Overall: 1st/99, WINNER of the Spaceport America Cup!